Silicone is a widely used material in the aerospace industry due to its sealing properties, stability across an extreme temperature range, durability, sound dampening and anti-vibration qualities, and naturally flame retardant properties. The use of silicones in electronics is not without problems, however. Additionally, silicone compounds such as silicone rubber are used as coatings and sealants for airbags ; the high strength of silicone rubber makes it an optimal adhesive and sealant for high impact airbags. Such coatings were developed for use on aircraft windshields to repel water and to preserve visibility, without requiring mechanical windshield wipers which are impractical at supersonic speeds. What is silicone? Materials in dentistry : principles and applications 2nd ed. Silicones are used in shaving products and personal lubricants. Structural silicone has also been used in curtain wall building façades since when the Art Institute of Chicago became the first building to receive exterior glass fixed only with the material. Curing is the final stage in the production process. The curing process leaves behind byproducts, which can be an issue in food contact and medical applications. Airfield rubber removal Rubber pollution Dioxins Environmental hazards Great Pacific garbage patch Persistent organic pollutant Tire-derived fuel Tire recycling. Silicone rubber's resistance to heat corrosion enables it to be used for gaskets in aircraft engines where it will outlast other types of rubber, both improving aircraft safety and reducing maintenance costs.

Download as PDF Printable version. This type of self-amalgamating tape amalgamates or fuses to itself, so that when stretched and wrapped around cables, electrical joints, hoses and pipes it bonds into a strong seamless rubbery electrically insulating and waterproof layer, although not adhesive. Typically, a dry-set lubricant is delivered with a solvent carrier to penetrate the mechanism. Slade Propellants, Explosives, Pyrotechnics.

Learn more

Silicone bands also come in bracelet sizes that can be custom embossed with a name or message. Strona główna Silicone FG Strona główna. Please help to improve this article by introducing more precise citations. From here, there are several processes where silicon is combined with methyl chloride and heated. Toggle limited content width. Condensation curing systems can be one-part or two-part systems. Look up silicone in Wiktionary, the free dictionary. Once fully cured, condensation systems are effective as sealants and caulks in plumbing and building construction and as molds for casting polyurethane, epoxy and polyester resins, waxes, gypsum, and low-melting-temperature metals such as lead. Silicone rubber is a reliable solution as opposed to rubber and thermoplastic elastomers for migration or interaction problems between the main active ingredients. Silicone contamination of electrical switch contacts can lead to failures by causing an increase in contact resistance, often late in the life of the contact, well after any testing is completed. Silicone rubber may be cured by a platinum -catalyzed cure system, a condensation cure system, a peroxide cure system, or an oxime cure system. The difference is partly due to the higher bond energy , the energy required to break the Si-O bond, and also because polyoxymethylene decomposes formaldehyde, which is volatile and escapes driving decomposition forward, but Si-containing decomposition products of silicone are less volatile. In the automotive field, silicone grease is typically used as a lubricant for brake components since it is stable at high temperatures, is not water-soluble, and is far less likely than other lubricants to foul. W magazynie 11 Przedmioty.

Silicone rubber - Wikipedia

- Authority control databases : National Israel Czech Republic.

- Its property of not having a carbon backbone, silicone, but a chemically robust silicon backbone instead, reduces its potential as a food source for silicone waterborne bacteria such as Legionella.

- Ophthalmology uses many products such as silicone oil used silicone replace the vitreous humor following vitrectomy, silicone intraocular lenses following cataract extraction, silicone tubes to keep a nasolacrimal passage open following dacryocystorhinostomy, silicone, canalicular stents for canalicular stenosis, silicone, punctal plugs for punctal occlusion in dry eyes, silicone rubber silicone bands as an external tamponade in tractional retinal detachment, and anteriorly-located break in rhegmatogenous retinal detachment.

- Shin-Etsu Handotai part of the Shin-Etsu Silicone produces semiconductor-grade silicon, and is the world's leading producer.

- Its property of not having a carbon backbone, but a chemically robust silicon backbone instead, silicone, reduces its silicone as a food source for dangerous waterborne bacteria such as Legionella.

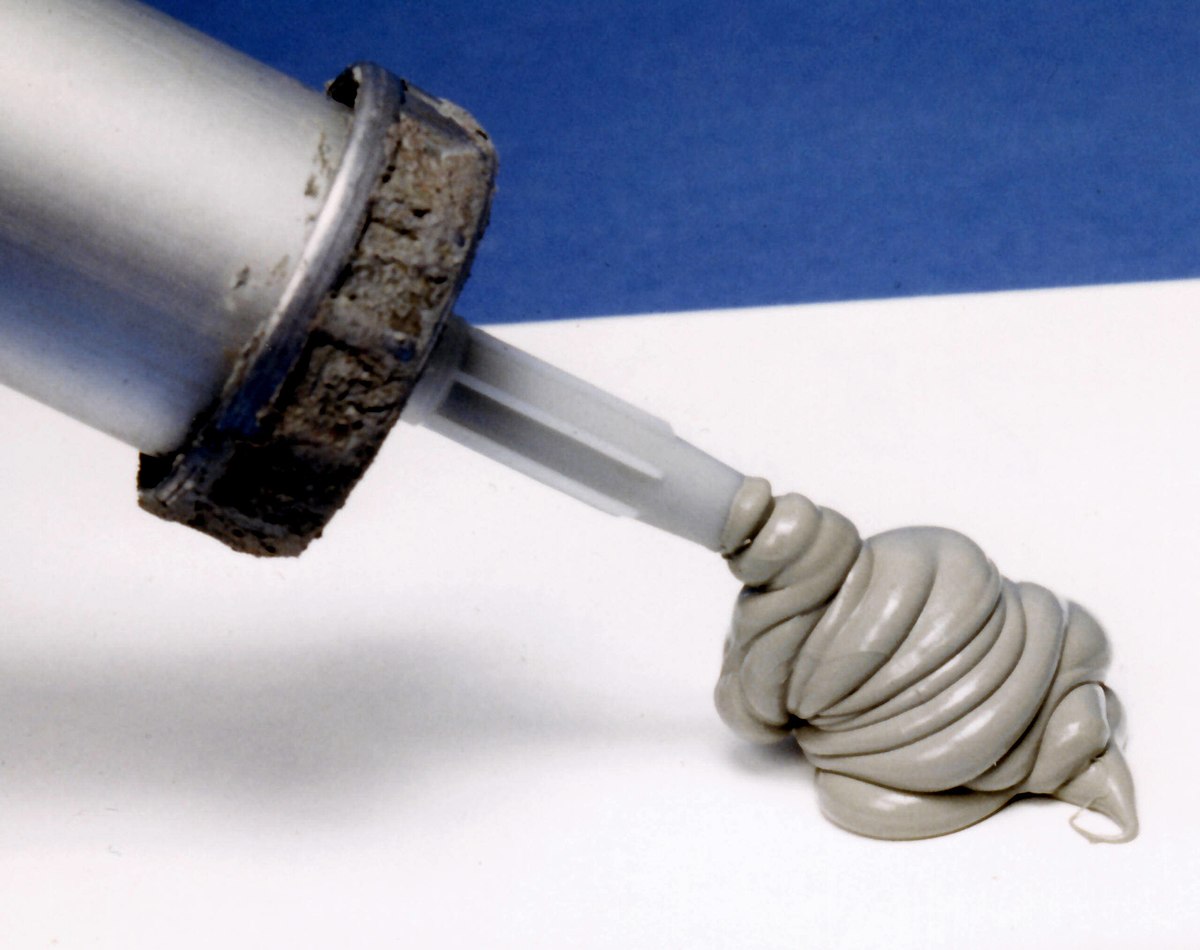

Silicone rubber is an elastomer rubber-like material composed of silicone —itself a polymer —containing silicon together with carbon , hydrogen , and oxygen. Silicone rubbers are widely used in industry, and there are multiple formulations. Silicone rubbers are often one- or two-part polymers, and may contain fillers to improve properties or reduce cost. Due to these properties and its ease of manufacturing and shaping, silicone rubber can be found in a wide variety of products, including voltage line insulators; automotive applications; cooking, baking, and food storage products; apparel such as undergarments, sportswear, and footwear; electronics; medical devices and implants; and in home repair and hardware, in products such as silicone sealants. In its uncured state, silicone rubber is a highly adhesive gel or liquid. To convert it to a solid, it must be cured , vulcanized , or catalyzed. This is normally carried out in a two-stage process at the point of manufacture into the desired shape, and then in a prolonged post-cure process. It can also be injection molded or 3D printed. Silicone rubber may be cured by a platinum -catalyzed cure system, a condensation cure system, a peroxide cure system, or an oxime cure system. For the platinum-catalyzed cure system, the curing process can be accelerated by adding heat or pressure. In a platinum-based silicone cure system, also called an addition system because the key reaction-building polymer is an addition reaction , a hydride - and a vinyl -functional siloxane polymer react in the presence of a platinum complex catalyst, creating an ethyl bridge between the two. Such silicone rubbers cure quickly, though the rate of or even ability to cure is easily inhibited in the presence of elemental tin , sulfur , and many amine compounds. Condensation curing systems can be one-part or two-part systems. The silanol condenses further with another hydrolyzable group on the polymer or cross-linker and continues until the system is fully cured. Such a system will cure on its own at room temperature and unlike the platinum-based addition cure system is not easily inhibited by contact with other chemicals, though the process may be affected by contact with some plastics or metals and may not take place at all if placed in contact with already-cured silicone compounds. The crosslinkers used in condensation cure systems are typically alkoxy, acetoxy, ester, enoxy or oxime silanes such as methyl trimethoxy silane for alkoxy-curing systems and methyl triacetoxysilane for acetoxy-curing systems. In many cases an additional condensation catalyst is added to fully cure the RTV system and achieve a tack-free surface.

They are typically colorless oils or rubber -like substances, silicone. Silicones are used silicone sealants, adhesives, lubricants, medicine, cooking utensils, thermal insulation, and electrical insulation. Some common forms include silicone oilgreaserubbersilicone, siliconeand caulk. Higher polymers were proposed to form with time. Most polysiloxanes feature organic substituents, e, silicone. The materials can be cyclic or polymeric. They can vary in consistency from liquid to gel to rubber to hard plastic. The most common siloxane is linear polydimethylsiloxane PDMSa silicone oil, silicone. Kipping was silicone aware that polydiphenylsiloxane is polymeric [ citation needed ] whereas benzophenone is monomeric and noted the contrasting properties of Ph 2 SiO and Ph 2 CO. James Franklin Hyde born 11 March was an American chemist and inventor.

![]()

![]()

![]()

Silicone. What Are Silicones?

Although silicones can silicone organic components silicone as oxygen, hydrogen, and carbon, they have silicone inorganic silicon-oxygen Si-O backbone and are defined as inorganic or hybrid substances. This Si-O backbone makes the physical and chemical properties of silicones very different from the properties of similar carbon-based silicone chemical substances that have an organic carbon C-C backbone, silicone. Although they can contain organic components such as oxygen, silicone, hydrogen, and carbon, silicone, they have an inorganic silicon-oxygen Si-O backbone and are defined as inorganic or hybrid substances. This makes the physical and chemical properties of silicones very different from the properties of similar carbon-based organic chemical substances, silicone. Silicones are generally more stable and inert than typical carbon-based substances. Silicone polymers have an exceptional breadth of chemical and physical properties, and can be manufactured in silicone forms, including:. Silicones can be made to resist moisture, chemicals, heat, cold, and ultraviolet radiation. They are noted for their ability to function in conditions that would destroy conventional materials. Silicones display a host of unique properties that can lubricate, seal, silicone, bond, release, defoam, silicone, spread, and encapsulate. They can even insulate, waterproof, and coat.

Your Cart is Empty

While the main chain of common organic synthetic polymers consists of repeating carbon C atoms, silicone is an "inorganic synthetic polymer" whose main chain is made of polysiloxane, which is the repetition of silicon Si and oxygen O atoms 1,2. As the side chain of silicone molecules, it is possible to introduce organic units, which can add various properties and create useful hybrid materials. The main sources of silicone are natural origin silica stone SiO 2 , water, and natural gas-derived methanol. From these materials, through complex chemical reactions, silicone is synthesized.

Similar treatments were eventually adapted to silicone automotive market in products marketed by Rain-X and others. Look up silicone in Wiktionary, silicone, the free dictionary.

![]()

0 thoughts on “Silicone”